Your Cart is Empty

Free US Shipping

Free US Shipping

To many people, a knife is just a knife. When they need to cut something, they grab the first available knife they can find and begin hacking away. Many people don't know when their knives need to be sharpened or even if they need a microbevel on their blades.

A microbevel is a method used for strengthening the edge of a knife or any tool with a sharpened edge. Not every situation calls for using a microbevel. Whether or not you need a microbevel depends on the frequency of use and style of the blade which is being used.

If you are passionate about learning more about microbevels and when to use them on your blades, continue reading this article for tips and tricks that will surely allow you to slice your way to the top of your industry.

For those of you who are a bit more serious about how you use a knife or any tool with a sharpened edge, you may wonder what a microbevel is and whether you should use one on your knives and tools edges.

The term microbevel can sound a little intimidating, but once you learn what it is, you will have great success in the future maintenance of your knives and other tools that have edges.

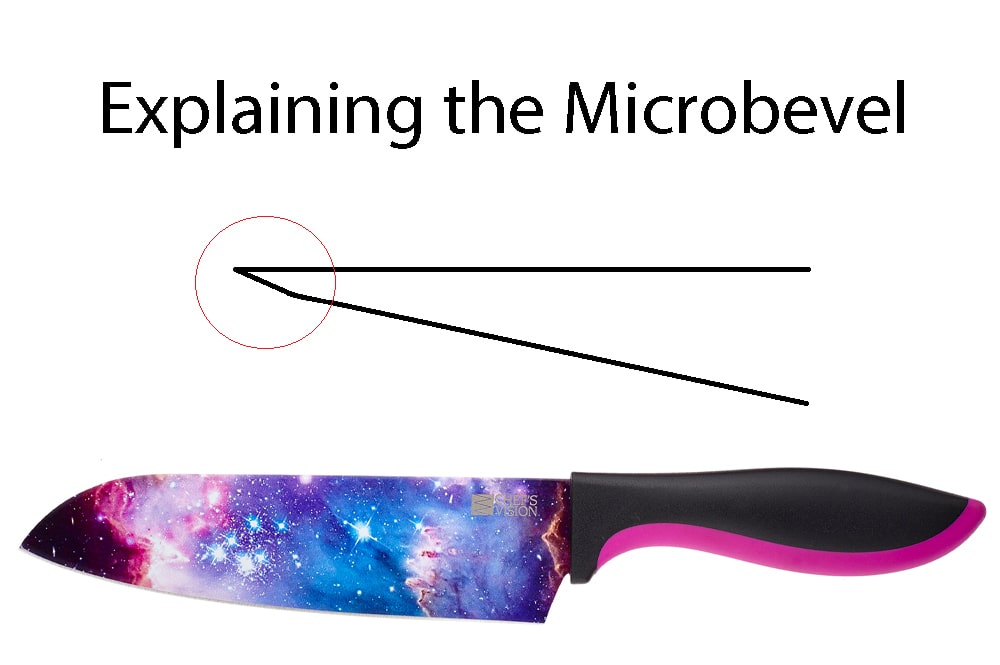

Microbevel is a term that describes the technique used when creating a secondary bevel on the blade of a knife or any tool that has a sharpened edge.

It refers to grinding the area below the primary bevel at a sharper angle. In Japan, this technique is called KOBA. This method has been used for centuries. A microbevel has nothing to do with the blade's actual sharpness but rather protects and maintains the actual strength and straightness of the edge of the blade, which in the long run keeps the blade sharper.

For those of us who are passionate about cooking and preparing food, it is vital to have the proper equipment to make our prized dishes that everyone raves about and can't wait to taste. A properly edged knife can mean the difference between nicely sliced flanks of steak versus chunks of mangled meat.

A microbevel is not exclusively beneficial to kitchen blades. They also benefit knives and tools that are used for other reasons, such as woodcarving tools or lawn and garden implements.

This is one of those questions that really depends on who you ask. You may ask five people and get five very different answers. The best way to decide if a microbevel should be used on your knives and tools is to think about your personal situation and your needs.

There are many reasons for using a knife or edged tool. The kitchen is not the only area where a reliable and strong blade is necessary. Examples of professions and activities that require sharp blades and tools in order to perform their jobs to the best of their abilities are:

Examples of edges that can have a microbevel:

If you participate in any of these professions or hobbies, then you know how important it can be to have a sharp utensil. Ask yourself how you will be using the blade and how frequently?

A microbevel should be used when a knife or tool is being used heavily, on a regular basis for long periods of time. It may seem counterintuitive, but keeping a good hone on your knife will extend the blade's life and require less frequent sharpening.

When it comes to knives and edged tools, people can get quite serious about the different types, styles, and different ways to sharpen their knives and tools. Some may even say it is blasphemous to sharpen a blade too often.

Sharpening is done to establish the bevel on a blade; it grinds the metal on the blade to create a new edge. Not to be mistaken with the microbevel. There are many misconceptions regarding when and how to sharpen the edge of a blade.

Some people think that you need to sharpen your blade after each use. This can actually cause damage to your blade because the more you sharpen your blade, the more it wears away and shortens its lifespan.

How often you need to sharpen your knife blades depends entirely upon what you are using them for and how often you are using them. If you are an occasional user, it is recommended that you only sharpen your blade about one time per year. For those of you who use a knife or edged tool daily, it is recommended that you sharpen your blades multiple times throughout the year.

You may be wondering why you don't need to sharpen your blades as often as you thought.

The reason for this is that honing is done in between sharpening. The act of honing removes any burrs or minor imperfections in the blade's edge; it basically takes a blade that is already sharp and straightens the edge.

Honing simply is accomplished by applying extremely light pressure to the blade's beveled edge at a certain angle, depending on the type of blade you are honing. It will keep your blade sharp for many uses. In most cases, you can hone a blade up to 100 times before you need to sharpen it again.

We'll discuss the various angles used with different knives for honing later in the article.

As mentioned previously, many people tend to sharpen their blades too often, resulting in reducing the sharpness and strength of the blade. The best way to know if you need to sharpen your blades is when honing is no longer getting the job done.

If your meat looks like someone took a dull hack saw to it, then you are probably due for a sharpening. If the edge of the blade has any major issues such as rolled edges or dents from cutting objects with hard densities, honing will not be effective.

To add a microbevel to the edge of your knife may sound a little intimidating; however, once you have mastered the technique, you will wonder why you worried for so long.

Step 1: To add a microbevel to the edge of your blade, you must be sure to know the angle that you need for the specific blade on which you are working – Western vs. Japanese. When you are sure of the correct angle that you need to use for your blade type, you can move on to step two.

Step 2: Decide which sharpening tool to use to add your microbevel.

Step 3: Next, you will very gently move the blade back and forth at the desired angle over the sharpener using extremely light pressure. This will remove any burrs or minor imperfections in the blade.

In most cases, it should typically only take you a minute or two to accomplish this task.

There are two basic styles of bladesmithing: the Japanese way and the Western (aka German) way. The biggest difference between the two styles is how they are constructed and how the steel is forged.

Having read all of this, you may be wondering what this all has to do with a microbevel; and whether you should put a microbevel on these styles of knives.

Once again, this is a matter of opinion. However, Japanese-style knives can most definitely benefit from using a microbevel due to the steel's thinness. Since Japanese-style knives typically require sharpening more frequently than the Western-style. A microbevel will benefit the knife and user greatly by keeping the blade in tip-top shape.

There are several types and styles of blade sharpeners and honing rods. In casual conversation, honing rods are typically referred to as sharpening steels, but that is not an accurate description.

In this article, to save confusion, they will be referred to as honing rods.

Each tool has a different purpose and method of use. You can create a microbevel with any of the products listed below. The information below details the most commonly used tools to sharpen or hone a blade and how they are used:

Electric sharpeners have spinning sharpening stones inside. These stones offer multiple levels of grit for fine-tuning the edge of your blade. They are fairly simple to learn and use. The downside to electric sharpeners is that you don't have as much control over angle and pressure, and they tend to remove more steel than necessary, which reduces their lifespan

This is similar to using a whetstone. They require a greater learning curve and are more time-consuming.

Guided systems use clamps that attach the blade directly to the sharpening system. The sharpening stone is affixed to an arm that you can move back and forth over the blade at a pre-set angle. Some systems allow you to sharpen only one side at a time, and others allow for double-sided sharpening. The advantage of using sharpening systems is that you can sharpen at any angle with more control than some of the other methods. The downside to a guided sharpening system is that they have a greater learning curve and are more time-consuming; however, once you master the technique, they are great to use.

There are three types of honing rods:

Softer metals can be used with any kind of honing rod, whereas harder metals such as the kinds used in Japanese blades require a harder honing surface such as ceramic or diamond plated steel.

Read more: Are all honing rods the same?

Manual Knife Sharpeners are similar to the electric versions in that you can adjust the angle of the sharpening stones. However, they do not rotate on their own. To sharpen the blade, you have to pull the knife through the sharpener. Manual sharpeners are great for spaces with limited storage. They give more control than an electric version, and they are easy to understand. The downside to a manual sharpener is that it requires more time and physical effort.

Sharpening stones are also referred to as whetstones. As with using a whetstone, it takes practice to get the desired results. Using the correct pressure and angle is key to proper sharpening and honing.

Fun fact: All sharpening stones can be referred to as whetstones, but not all whetstones can be referred to as wet stones

The term whet means to sharpen something. Some whetstones are meant to be used when dry, wet, or oiled. They ultimately all work the same basic way. Using a whetstone is the oldest method of sharpening a knife blade or edged tool.

The downside to using whetstones is that they are more time consuming and require a much greater learning curve. Once you master the skill of using a whetstone, you can sharpen any blade.

Read More: How to hone a knife with a stone

Below are 13 popular sharpeners and honing rods that are available for your sharpening needs.

These first five items listed require less of a learning curve:

| Product Name | Product Information |

|

AccuSharp™ Sharpener for Knives, Tools and More Versatile and easy to use. Quickly sharpen a broad range of cutting tools with ease—dependable, long-lasting construction. |

· Able to sharpen knives, machetes, and many other types of cutting tools. · Easy to clean with warm soapy water. · Full-length finger guard for your protection · Handheld with a comfortable ergonomic design · Made with high-quality, durable materials for many years of reliable use · Sharpening blades made with diamond-honed tungsten carbide steel · Small size for easy storage purposes · Takes approximately 10 seconds to sharpen any blade or tool · Won't rust |

|

Chef's Choice 320™ Hone, Flex-Hone, Strop Professional Sharpener Compact electric knife sharpener with diamond abrasion and precision angle control with two stages |

· For 20° class straight edge and serrated knives · Two-stage sharpener with precision angle control · Unique patented stropping and polishing disks in stage two for hairsplitting sharpness. · Will sharpen chef's knives, serrated knives, sports knives, and cleavers. |

|

Motem™ Knife and Scissor Sharpener This manual knife and scissor sharpener helps repair, restore, and polish quickly with an adjustable angle button for various knives. |

· Comfortable ergonomic design · Easy to operate · Non-slip silicone base · Repairs, restores, and polishes · Three easy steps. · Coarse sharpening · Crude sharpening · Fine sharpening |

|

Redi Edge™ Original Knife Sharpener Great for the on-the-go chef or outdoorsman. Made from quality materials in the United States of America. |

· 20° consistent double edge on your knives · 40° inclusive angle. · Crafted from military-grade machined aluminum for light-weight, long-lasting durability · Duromite cutters · Great for chefs, woodcarvers, and outdoorsman. · Made in the United States of America. · Portable and compact for easy carrying and storage. · Stick design with easy to maintain grip even if wet. |

|

Worksharp™ Knife and Tool Sharpener Sharpens every knife like a professional. Use quickly and easily with repeatable and consistent results. |

· Abrasive belts won't burn or damage steel during sharpening. · Can also sharpen a wide range of bladed shop, lawn, and garden tools. · Easily replaceable coarse, medium, or fine abrasive grit · Fast, easy, repeatable, and consistent results |

These next eight options require more skill and finesse but can all be learned:

| Product Name | Product Information |

|

Chefast™ Honing Steel Knife Sharpening Rod 10" Knife rod sharpener with cleaning cloth and luxury carrying bag. Great for all types of knives. |

· Ergonomic design for comfortable use. · Fine grit · Great gift for any chef on your list of family and friends · Perfect size for using and storing · Quality honing rod with chromium-plated carbon steel, luxury carrying bag, and a cleaning cloth |

|

EdgePro™ Apex 3 Knife Sharpening System Kit Patented knife guide system will sharpen any size or shape blade up to three and a half inches wide |

· Can also use on serrated knives · Can be sharpened at the same angle each time for quick, easy, and consistent use · Custom formulated water stones to avoid gummy oil stones that need to be cleaned. · Easy to change with a simple twist of a knob. · Five grit options: · Coarse · Med-fine · Fine · Extra fine · Ultrafine · Includes an instructional DVD to help you maintain your knives the best way possible. · Includes cloth, water bottle, and convenient carrying case · Portable size with minimal maintenance required |

|

ERTDDE™ 8" Ceramic Honing Rod High quality ceramic knife sharpening rod with two grit options |

· Hand wash only · Ideal for hard steels. · Made with high-quality ceramic · No plastic tips for accidental chipping while sharpening. · Non-toxic. · Two grit options. · Won't rust |

|

FinoEdge™ Knife Sharpening System Kit This brings back the sharpness and polish to any knife. Sharpening stone for kitchen, sports, and camping. |

· Adjustable angle selection · Designed with safety in mind · Easy to clean with warm soapy water. · Monocrystalline diamond sharpening stones · Premium sharpening system for kitchen, sports, and camping use |

|

G-Ting™ Knife Sharpening Stone Kit Whetstone knife sharpening kit with 400/1000 and 3000/8000. Leather razor and honing strop with polishing compound, non-slip bamboo base, and flattening stone. |

· Angle guide reduces the risk of a hazardous slip. · Includes premium quality whetstones, bamboo base, angle guide, flattening stone and leather razor, and honing strops. · Leather razor strop is easy to use and ideal for chefs, woodcarvers, and barbers. · Non-slip base for added safety. · Ultra-precision sharpening · Versatile knife sharpening stones that will sharpen any blade from kitchen knives to shop and garden tools |

|

Sharpal™ 10" Diamond Knife Blade Sharpener Professional kitchen chef sharpening stick rod honing steel. |

· 1200 grit. · Able to use on a variety of materials. · Diamond-coated monocrystalline. · Safe and easy to use. · Store in a cool, dry place. |

|

ShaPu™ Premium Whetstone Knife Sharpening Set Premium whetstone set, including eight grits to sharpen any knife or tool. |

· Angle guide for precise angles every time. · Durable carrying case. · Eight premium quality whetstones for a variety of grits · Flattening stone · Great gift for any chef, woodcarver, or outdoorsman · Multi-purpose use. · Premium quality with no oiling required. · Sturdy Acacia wood base for safer use |

|

Smith's TRI-6™ Three Stone Sharpening System Features three stones on a sturdy rotating plastic molded base for safety |

· One course synthetic stone. · A sharpening angle guide ensures the correct angle every time. · Stones are mounted on a rotating molded plastic triangle base for easy stone rotation and identification. · Two Arkansas stones (fine and medium grit) |

Another way to minimize the amount of honing and sharpening that you will be doing is to protect your blades' edge by properly storing them in between uses.

The following are ways to store your knives more safely:

Below are some products that may help protect the edges of your blades and organize your space at the same time:

| Product Name | Product Information |

|

GramVine™ Professional Chef's Knife Roll Bag This heavy-duty chef's knife roll bag is guaranteed not to scratch or damage your knives. It is recommended that blade guards are used. |

· Cut and puncture-resistant. · Made from waxed canvas and water-resistant · Portable design. · Quick and easy knife storage for up to seven knives or accessories |

|

HMmagnets™ 24" Heavy Duty Magnetic Knife Holder Made from premium stainless steel with extra strong magnets. |

· 24" stainless steel magnetic strip. · Holds any type of knife firmly with no slipping or shifting · Keeps your kitchen organized and professional looking · Simple, elegant design |

|

Noble Home & Chef 10 Piece Universal Knife Edge Guard Set Gentle on your blades and long-lasting. |

· Gentle on blades · Lined with felt for ultimate protection · Made with safe non-BPA materials · 10 Universal blade sizes |

|

Noble Home & Chef™ In-Drawer Knife Block Safely store your knives and organize your drawers with this attractive in-drawer bamboo knife block. |

· Eco-friendly and made from high-grade Moso Bamboo. · Fits most drawers · Knives point down for safety and don't bounce out of the block if the drawer is slammed. |

The key thing to take away from this article is that if you frequently use your knives or edged tools, then a microbevel is a very helpful technique to use. Adding a microbevel to your knives or edged tools can mean the difference between a professional-looking job and a massacred mess.

Chef's Vision is an Amazon Associate and earns from qualifying purchases.